Odor Control Study SulFeLox® Versus Calcium Nitrate

Background:

Faced with increased chemical prices, a large facility in Tennessee wanted to trial Sulfelox® as a potential alternative to their Bioxide program. USP Technologies was brought in to prove that SulFeLox® could replace nitrate at a 3:1 volume ratio which in a long-term program opens the door for cost savings up to 25%. Additionally, the program would need to provide similar H2S performance (<10ppm vapor average) to ensure the life cycle of the manifolded force mains. PS 1 feeds into a dual 12” force main that has three smaller force mains that manifold in before discharging at the control point downstream. PS 1, PS 2, and PS 3 are all equipped to use Bioxide for sulfide control at the discharge and have performed well for over 20 years. The retention time for this force main is relatively long (7-8 hours), and provides a perfect application to switch to SulFeLox® for hydrogen sulfide control. In June of 2023, the city turned off their chemical feed to establish baseline conditions, followed by 30 days of dosing SulFeLox® at Pump Station 1.

Technology

SulFeLox® is a buffered iron solution that combines the effectiveness of iron salts with the safety benefits of calcium nitrate – all at less cost. It is specifically designed to control H2S in wastewater collection systems by binding it into non-volatile ferrous sulfide (FeS). It contains no free acid and has a lower hazard rating than traditional iron salttechnologies, and equal or lower than calcium nitrate, enabling use in residential and commercial areas. SulFeLox® can go anywhere nitrates can and is specifically designed to replace nitrate where it performs the worst – in long, slow-moving, sulfide generating sewers. Typical applications for SulFeLox® can substitute for nitrate on a 1:2 to 1:3 basis,meaning significantly fewer deliveries, and approximately 15-20% less cost.

Performance

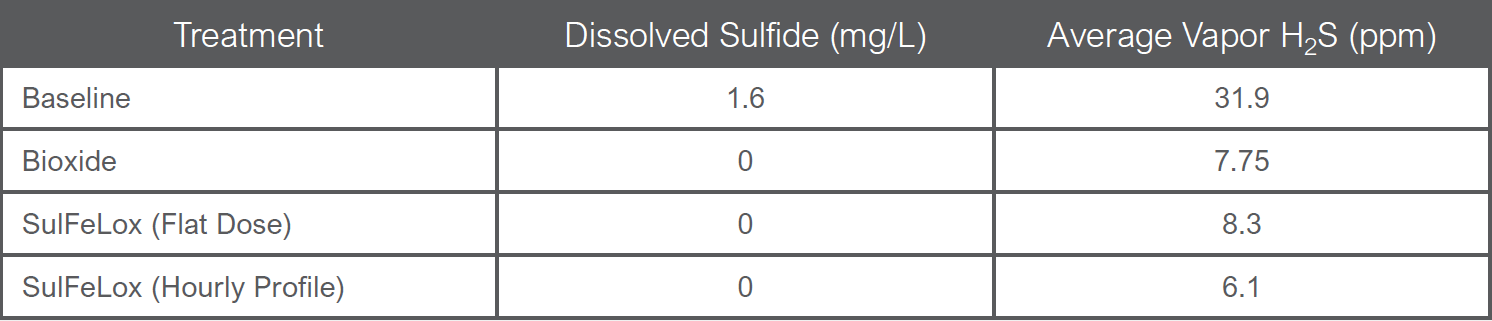

For program comparison, USP collected liquid and vapor H2S data in three scenarios.

USP Technologies produced the above results through the approximate replacement ratio of 3:1 of Bioxide with SulFeLox® within three weeks of system startup. Estimates provided for a year long program on this line would provide approximately 20% cost savings over the current treatment program in addition to reduced number of chemical deliveries. Finally, a 22% decrease in vapor H2S (ppm) levels was observed versus the same time period last year.

For the full case study, click here.

Featured Products

SulFeLox®– Low Hazard Iron Salt

A low hazard and cost effective alternative to traditional iron salts and calcium nitrate for controlling sulfide levels in collection systems.

Full-Service Solutions

USP provides turn-key chemical management and full-service field programs to engineering firms and remediation technology practitioners.

Iron Salts

A proven technology for long-duration H2S control in process water systems, solids processing units, solids transfer lines, and anaerobic digesters.

USP Technologies

5640 Cox Rd.

Glen Allen, VA 23060

Toll-free (800) 851-8527

Phone (804) 404-7696

USP - Canada

3020 Gore Road

London, Ontario N5V 4T7

Toll-free (800) 851-8527

Phone (804) 404-7696

Contact Us

Our sales engineers are ready to help you find the right solution. Fill out the form to connect with your local USP Technologies representative.

"*" indicates required fields