Cooling Tower and Process Water Treatment

Cooling Tower and Process Water Treatment

The unique properties of hydrogen peroxide (H2O2) make it a good technology for keeping cooling loops, process water loops and heat exchangers clean from fouling that can occur due to various contaminants in the water. H2O2 works well in removing organic fouling on surfaces through mechanical means and in specific applications through biocidal mechanisms.

Hydrogen peroxide can be used in a shock treatment mode where it is fed based on a timer set-up. It can also be used occasionally at higher concentrations for maintenance cleaning purposes of fouled heat exchangers, cooling water loops and process water loops. Performing an occasional shock cleaning of a heat exchanger with hydrogen peroxide can remove buildup from surfaces and can result in improved heat transfer efficiency. By removing surface fouling, hydrogen peroxide may also improve the efficiency of other biocides such as bleach, bromine and non-oxidizers.

Cooling Tower Cleaning Results

Read our cooling tower and evaporator cleaning case studies below!

Related Case Studies

Cooling Towers and Process Water System Cleaning Applications

The unique properties of hydrogen peroxide (H2O2) make it a good technology for keeping cooling loops, process water loops and heat exchangers clean from fouling that can occur due to various contaminants in the water.

Learn MoreIncreased Evaporator Performance

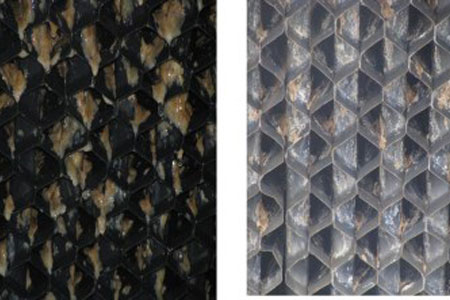

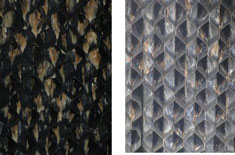

USP Technologies and a sugar beet processing plant in the US developed a cleaning strategy to use high concentrations of hydrogen peroxide to remove year-over-year burnt on scale inside multi-phase plate pack evaporators.

Learn MoreUSP Technologies

5640 Cox Rd.

Glen Allen, VA 23060

Toll-free (800) 851-8527

Phone (804) 404-7696

USP - Canada

3020 Gore Road

London, Ontario N5V 4T7

Toll-free (800) 851-8527

Phone (804) 404-7696