PRI-TECH™– Peroxide Regenerated Iron

PRI-TECH™(Peroxide Regenerated Iron Technology)

PRI-TECH™ is an innovative combination treatment that integrates iron salts with hydrogen peroxide (H2O2) in a unique and synergistic fashion, resulting in cost savings and treatment enhancement compared to traditional iron salt use.

The Problem

Iron salts (ferrous/ferric chloride or sulfates) are a widely used mainstay in traditional municipal wastewater treatment for both collection system and treatment plant applications including hydrogen sulfide control, solids separation and phosphorus removal. Oftentimes, a municipality is practicing one or more of these in combination to meet various treatment goals.

However, these applications are not synergistic: the product of the sulfide reaction is ferrous sulfide (FeS), a “spent” form of iron that is a tightly bound black precipitate (“pin floc”) that does not control additional H2S, or enhance solids separation, or remove phosphorus. Further, along with the remaining dissolved sulfide present, that FeS consumes ferric iron that is often added for CEPT and phosphorus removal.

Iron-Sulfur-Phosphorus Interactions

The key aspects of iron-sulfur-phosphorus (Fe-S-P) interactions underlying these applications can be characterized as follows:

- Ferric prefers to bind with phosphate; however

- Sulfide reduces ferric to ferrous; and

- Ferrous prefers to bind with sulfide

The implications of this characterization are many. For example:

- Fe3+ added for sulfide control at pump station influents and treatment plant headworks preferentially binds with phosphate (initially), allowing dissolved sulfide to (temporarily) go free, impairing odor mitigation efforts

- Sulfide present in the plant influent (either as dissolved or total) reduces (to Fe2+) the Fe3+ added to enhance settling and/or phosphorus removal through primary clarifiers. Further, the higher proportion of Fe2+ (soluble) to Fe3+ (insoluble) results in higher levels of Fe carrying over into secondary treatment where the Fe becomes bound into biomass, rendering it less available for sulfide and/or struvite control in anaerobic digesters.

- Dissolved sulfide present in the primary settled solids scavenges Fe added to the digesters for struvite scaling control. Higher levels of sulfide have also been shown to inhibit biogas production / solids reduction – one published survey indicated 30% of plants experience such inhibition – which has been attributed to the scavenging of essential micronutrients (especially Fe, Co, Ni) by sulfide.

- Sulfide present in the digester effluent reduces Fe3+ added for dewatering (to Fe2+) and then scavenges the Fe2+ – thereby impairing coagulation and increasing the loadings of phosphorus in the centrate / filtrate. This phosphorus loading, when returned to the plant influent and recycled back into process, can comprise 30-50% of the total plant phosphorus loading).

Results of Sulfide Presence

The result of sulfide presence is thus that supplemental or excess iron salt is needed to affect the desired results, which leads to increased costs and/or impaired treatment performance.

Direct costs:

- Chemical expenditures

- Associated overheads

Indirect costs:

- Higher solids production (disposal costs)

- Degraded water quality

- Reduced alkalinity

- Elevated salinity levels

- Depleted dissolved oxygen

It therefore makes sense to explore new ways to maximize the efficiency of Fe in order to reduce its costs – both direct and indirect.

The PRI-TECH™ Solution using Iron Salts and Hydrogen Peroxide

USP Technologies has addressed this need through development of its proprietary oxidative iron regeneration technology platform called PRI-TECH™ (Peroxide Regenerated Iron-Technology™). PRI-TECH™ is an innovative combination treatment that integrates iron salts with hydrogen peroxide (H2O2) in a unique and synergistic fashion, resulting in cost savings and treatment enhancement compared to traditional iron salt use.

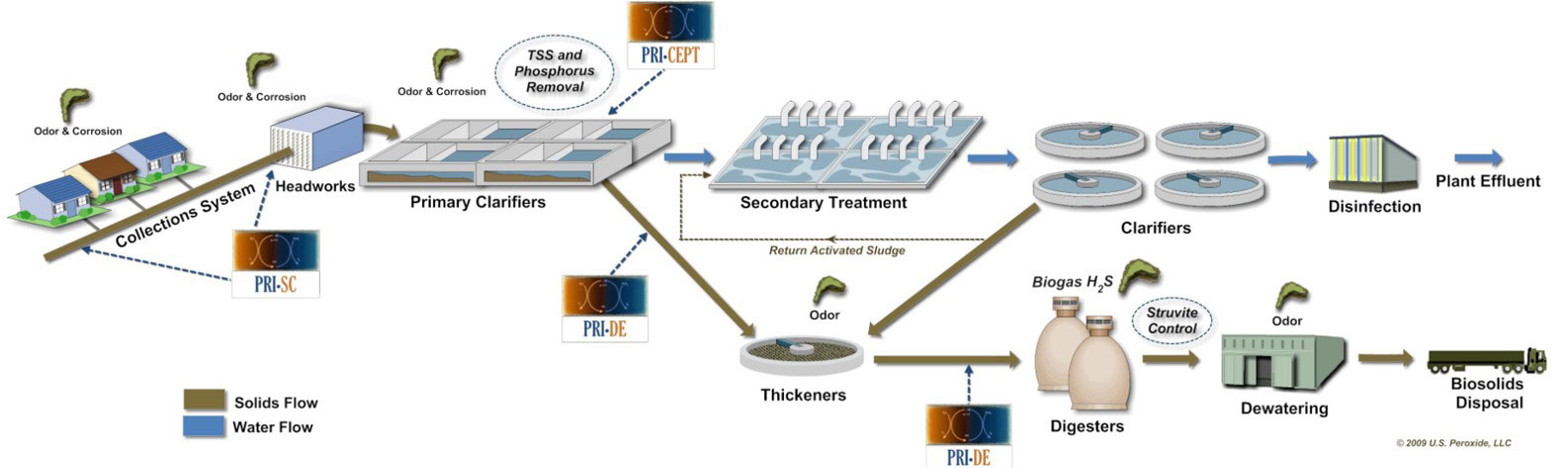

The PRI-TECH™ platform includes an integrated suite of applications including:

-

PRI-SC® for hydrogen sulfide control in collection systems and headworks

-

PRI-CEPT® for enhancement of advanced primary treatment (e.g. CEPT) and phosphorus removal

-

PRI-DE® for digester enhancement and biosolids processing

How Does PRI-TECH™ Work

At the most basic level, PRI-TECH™ treatment may be viewed as an oxidant (hydrogen peroxide) regenerating the spent iron salt (FeS) in-situ, yielding either fresh ferrous (Fe2+) or ferric (Fe3+) iron and colloidal sulfur. The regenerated iron can then be used for subsequent downstream applications the same as if fresh or excess iron salt were being added. In the context of PRI-TECH™, H2O2 thus serves as an oxidant to produce and maintain free ferrous ions from FeS (if dosed at low levels) and/or Hydrous Ferric Oxides (if dosed at higher levels). In this way, H2O2 may be used in an appropriate manner to direct Fe between bound and unbound forms, and/or solid or liquid states.

At the highest level, PRI-TECH™ provides a municipality an Intra-Plant Iron Management (IPIM) approach: a subordinate operational strategy that sits on top of existing WWTP strategies and intervenes at specific points in the treatment process to chemically transform Fe from one state to another – be that Fe2+ or Fe3+, soluble or insoluble, free or complexed. This ‘directed Fe’ can then be subsequently used for the targeted treatment need.

The net effects are equal or better treatment performance, reduced overall iron salt use, and lower treatment cost. Other benefits are accrued to the reaction, including: reduced solids (FeS) loadings, accelerated sulfide oxidation reaction rates, and preservation of ferric iron addition for solids separation and/or phosphorus removal.

Related Case Studies

Biosolids Odor Control via PRI-TECH®

A field demonstration was initiated in February 2014 by the Suffolk County Department of Public Works (SCDPW) to quantify the impacts of Peroxide Regenerated Iron-Technology (PRI-TECH®).

Learn MoreSoutheast Municipal Wastewater Odor Control

This is a sample 7,800 gallon ferrous chloride (FeCl2) storage and dosing system installation within the collection system of a large Southeast municipality.

Learn MoreUSP Technologies

5640 Cox Rd.

Glen Allen, VA 23060

Toll-free (800) 851-8527

Phone (804) 404-7696

USP - Canada

3020 Gore Road

London, Ontario N5V 4T7

Toll-free (800) 851-8527

Phone (804) 404-7696

Contact Us

Our sales engineers are ready to help you find the right solution. Fill out the form to connect with your local USP Technologies representative.

"*" indicates required fields