Advanced Oxidation for High Strength Caustic Wastewater

A refinery in the Northeast was looking at options to dispose of 10,000 bbls of high strength, high pH caustic wastewater that had been stored in one of its tanks. The wastewater had very high phenol levels (14,000 mg/L), and did not allow for processing through the activated sludge system due to biological toxicity issues. Off-site, hazardous waste treatment options were available, but would have cost over $600,000. A less expensive, temporary, non-capital and on-site treatment approach that would eliminate the phenols and allow for processing through the activated sludge system was evaluated and implemented at this facility. Earlier in the year, the refinery had a major activated sludge system upset caused

by high chemical oxygen demand (COD) loading that killed the nitrifying bacteria and lowered the dissolved oxygen (DO) levels, which made it difficult to recover and achieve required ammonia removal. USP Technologies (USP) successfully solved this problem using hydrogen peroxide for sulfide oxidation and supplemental DO, which helped the activated sludge system recover and created an environment that allowed the nitrifying bacteria to reestablish. Having successfully solved this problem, USP was asked to look at the high-strength, high pH caustic water in order to determine if it could be treated on-site and processed through the activated sludge system in a safe and economic manner.

Phenols are easily oxidized using advanced oxidation chemistry, which has been used for decades in order to break down organics. Many metals have special oxygen transfer

properties, which improve the utility of hydrogen peroxide. In aqueous solutions, hydrogen peroxide will react with trace amounts of iron to generate the highly reactive hydroxyl

radical (OH*). This process is known as Fenton’s Reagent and the chemistry is as shown:

Fe2+ + H2O2 → Fe3+ + OH- + -OH

Fe3+ + H2O2 → Fe2+ + •OOH + H+

The hydroxyl radical is one of the most potent oxidizers known (oxidation potential = 2.7 mV), and upon formation, readily initiates the oxidation of organic compounds via free radical mechanisms. The objective in this case is the oxidation of total phenolics in order to reduce the toxicity of the wastewater allowing for on-site processing through the activated sludge process. Fenton’s Reagent treatment is typically carried out in acidic solution, with an optimal pH range of 2.5 – 5.5. Fenton’s Reagent can also be performed at neutral pH using different catalysts. USP performed bench scale testing on and off-site in order to determine if Fenton’s Reagent chemistry could achieve the elimination of phenols and what the cost would be to perform this treatment on-site. The untreated wastewater had the following water quality characteristics:

Initial COD: 26,790 mg/L

pH: 12.6

Initial Total Phenolics: 14,000 mg/L

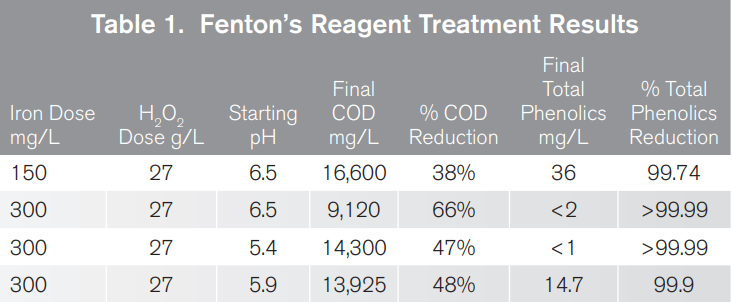

Table 1 summarizes the data from lab testing performed on-site as part of the final treatability tests:

The lab treatability testing clearly demonstrated that COD could be reduced by 47-66% and total phenolics by 99.9%. After achieving repeatable results in the lab, USP provided the

refinery with a turn-key proposal for on-site treatment of this particular wastewater.

USP mobilized and installed the equipment set-up for the daily batch treatment of the high strength wastewater. USP personnel processed the batches daily and confirmed phenol levels were below the stated refinery target of 100 mg/L before raising the pH above 7 to discharge to the refinery EQ tank that feeds the activated sludge process. Wastewater batches were processed by USP over a three month period, and the turn-key treatment cost was $300,000. This resulted in hard-cost savings to the refinery of over $300,000 versus off-site disposal.

The wastewater was treated in a safe and environmentally friendly manner, which allowed the refinery to process it through the activated sludge process without any negative effect on biology. On-site treatment also allowed the refinery to save a significant amount of money versus off-site disposal.

Download

Download the Case Study on Advanced Oxidation for High Strength Caustic Wastewater

USP Technologies

5640 Cox Rd.

Glen Allen, VA 23060

Toll-free (800) 851-8527

Phone (804) 404-7696

USP - Canada

3020 Gore Road

London, Ontario N5V 4T7

Toll-free (800) 851-8527

Phone (804) 404-7696

Contact Us

Our sales engineers are ready to help you find the right solution. Fill out the form to connect with your local USP Technologies representative.

"*" indicates required fields