Reducing H2S Emissions and Odor Complaints: SulFeLox® vs. Calcium Nitrate

Project Scope

The case study examines the effectiveness of using SulFeLox® to reduce problematic H2S emission and odor complaints from the community. The study evaluates the performance and cost-effectiveness of SulFeLox® as a replacement for Calcium Nitrate (CaN) in a high flow interceptor where chemical demands and community sensitivities are highest.

Background

USP Technologies along with the City of Portland and Carollo Engineers conducted a 6-week field demonstration comparing cost and performance efficiency of a low hazard buffered -Fe product (SulFeLox®) feeding at 86AV and FABA PS to compare performance and cost to their current calcium nitrate program. Extensive sampling and monitoring took place during the 6-week field demonstration looking at performance, usage rate, and cost comparing SulFeLox® to calcium nitrate at the force main discharge structure and downstream gravity interceptor.

Objective

Compare performance efficiency of low hazard buffered iron (SulFeLox®) to historical calcium nitrate for hydrogen sulfide odor control along the 86AV and FABA Pumping Station FM discharge and impact downstream of the gravity interceptor segments. The trial focused on the following:

- Reduce hydrogen sulfide odor generation at the 86AV and FABA Pumping Station force main discharge and downstream along the gravity segments of the interceptor.

- Document and log odor complaints during the duration of the trial and compare to historical odor complaints logged.

- Determine treatment cost and chemical usage at equal and improved performance to calcium nitrate at the 86AV and FABA Pumping Station discharge and downstream gravity segments of the interceptor.

Technology

SulFeLox® is a buffered iron solution that combines the effectiveness of iron salts with the safety benefits of calcium nitrate – all at less cost. It is specifically designed to control H2S in wastewater collection systems by binding it into non-volatile ferrous sulfide (FeS). It contains no free acid and has a lower hazard rating than traditional iron salt technologies, and equal or lower than calcium nitrate, enabling use in residential and commercial areas. SulFeLox® can go anywhere nitrates can and is specifically designed to replace nitrate where it performs the worst – in long, slow-moving, sulfide generating sewers. Typical applications for SulFeLox® can substitute for nitrate on a 1:2 to 1:3 basis, meaning significantly fewer deliveries, and approximately >15-20% less cost.

Solution/Results

Results from this trial showed that SulFeLox® provided superior control of H2S at the force main discharge and key downstream monitoring points at lower chemical usage and costs when compared to Calcium Nitrate. Significantly, there were zero community odor complaints received by the City of Portland during the 6-week SulFeLox® demonstration.

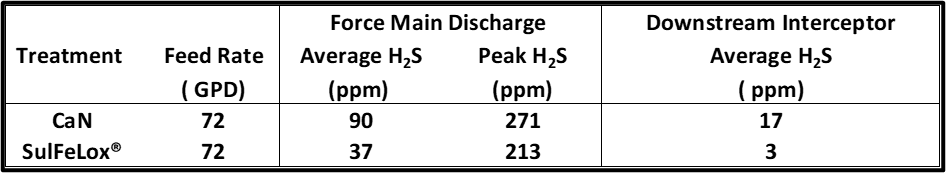

SulFeLox® compared to CaN at 72 gallons per day (GPD)

- SulFeLox® yielded an 59% decrease in average H2S levels at the FM Discharge when compared to the same rate to CaN.

- SulFeLox® yielded an 84% decrease in average H2S levels at Custer Street when compared to the same rate to CaN.

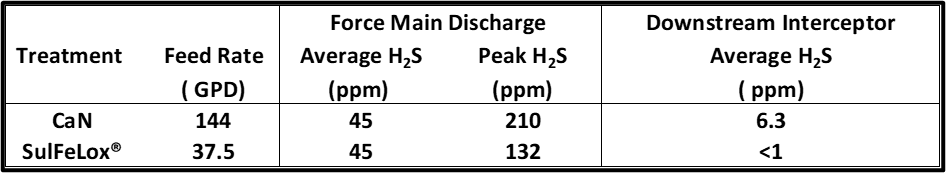

Optimization Vapor Phase H2S Data Target at Equal Performance

- 5GPD of SulFeLox® achieved equal performance to CaN at 144 GPD (3.84 gallons CaN: 1 gallon of SulFeLox®).

- SulFeLox® yielded an est. 38% reduction in peak levels at the FM discharge (210 ppm H2S vs. 132 ppm H2S)

- SulFeLox® yielded > 85% reduction on average H2S downstream interceptor (6.3 ppm H2S vs. <1 ppm H2S).

- It was evident that with addition of SulFeLox® at the Fanno PS, free iron (Fe2+/Fe3+) was regenerated at the FM discharge due to natural aeration, free iron was made available for additional sulfide binding in the downstream gravity segments.

Based on the trial at the City of Portland, the SulFeLox® technology provided equal to better performance when compared to calcium nitrate at the 86AV and Fanno Basin (FABA) pumping station FM discharge and downstream gravity interceptor segments. Results clearly validated that a reduction in chemical feed by 74% (37.5 gpd SulFeLox® vs 144 gpd calcium nitrate) and 60% (29 gpd SulFeLox® vs 72 gpd calcium nitrate) during the fall and winter seasons respectively. This would result in reduce chemical delivers and overall annual chemical expenditure of 25% for the City of Portland.

Featured Product

SulFeLox®– Low Hazard Iron Salt

A low hazard and cost effective alternative to traditional iron salts and calcium nitrate for controlling sulfide levels in collection systems.

USP Technologies

5640 Cox Rd.

Glen Allen, VA 23060

Toll-free (800) 851-8527

Phone (804) 404-7696

USP - Canada

3020 Gore Road

London, Ontario N5V 4T7

Toll-free (800) 851-8527

Phone (804) 404-7696

Contact Us

Our sales engineers are ready to help you find the right solution. Fill out the form to connect with your local USP Technologies representative.

"*" indicates required fields