Disinfection

Wastewater Treatment Plant Disinfection

Disinfection is the final and critical step before treated wastewater is released into the environment. It plays a vital role in protecting public health and preserving environmental quality. The disinfection process removes harmful pathogens that earlier treatment stages didn’t eliminate, helping prevent the spread of these pathogens in natural ecosystems.

A brief history of disinfection

In the early 20th century, chlorination became the standard method for wastewater disinfection. It was highly effective at oxidizing pathogens in treated wastewater. However, by the 1970’s, concerns grew over the environmental and human health impacts of chlorine and its byproducts.

As a result, strict regulations were introduced to limit chlorine residuals in treated effluent.

Modern disinfection technologies

Today, wastewater treatment plants use a variety of disinfection methods, including:

- UV radiation

- Ozone

- Chlorine

Additionally, emerging technologies are also gaining traction, such as:

- Performic acid

- Peracetic acid

- Ultrafiltration

These methods can be used individually or in combination to enhance disinfection performance, as explained here.

The importance of optimized dosing for disinfection

Choosing the right disinfection technology is only part of the equation. Optimized chemical dosing control is essential to:

- Ensure effective pathogen removal

- Avoid chemical overuse

- Maximize system performance

Advanced dosing control technologies can help facilities maintain compliance, reduce costs, and improve overall treatment outcomes.

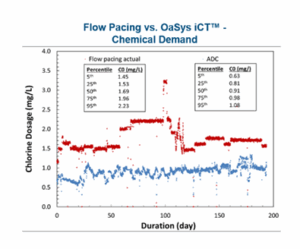

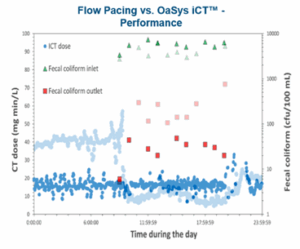

Advanced chemical dosing control with OaSys iCT™

OaSys iCT™ is an advanced, model-based disinfection control technology that helps wastewater treatment facilities (WRFs) optimize chemical dosing by accounting for system variability, helping to achieve more consistent performance, reduced chemical use, and better public health protection.

OaSys iCT™ uses real-time modeling to normalize disinfection performance. It takes into account key variables such as hydraulics, background chemical demand, and disinfection kinetics, and uses performance data to establish an optimal disinfection chemical dose, given flow and water quality conditions. As a result, the system allows for:

- Chemical Optimization

- Performance Precision

- Improved Effluent Quality

- Regulatory Confidence

OaSys iCT™ can help WRFs achieve more efficient, cost-effective, and environmentally responsible disinfection outcomes.

Click on the links below or contact us to learn how USP Technologies can help find the best disinfection option for your application.

Additional Content

USP Technologies

5640 Cox Rd.

Glen Allen, VA 23060

Toll-free (800) 851-8527

Phone (804) 404-7696

USP - Canada

3020 Gore Road

London, Ontario N5V 4T7

Toll-free (800) 851-8527

Phone (804) 404-7696

Contact Us

Our sales engineers are ready to help you find the right solution. Fill out the form to connect with your local USP Technologies representative.

"*" indicates required fields